We offer our customers a broad range of products and services in the fields of production, preventive and corrective maintenance, and the training needs of their teams of technicians and specialists.

Training on Analysis of failures in bearings and gears, and techniques for early detection of failures in wind turbine gearboxes

It can be said that every failure is unique. However, both bearings and gears exhibit cataloged mechanical signs and behaviors for wind turbine gearboxes that warn of malfunctions. The period from deterioration to failure might range from minutes to years, depending on the application and operating parameters. The longer it takes to detect failure, the greater the risk of major damage. For this reason, learning their detection and recognition is vital, along with counting on specialized support in their maintenance and repair.

At ABS WIND, we offer our customers the broadest range of products and services in the fields of production, preventive and corrective maintenance, and a solid response to the training needs of their teams of technicians and specialists.

Through the training courses, we share our expertise while listening and learning from the needs and concerns of our customers, particularly their technicians in charge.

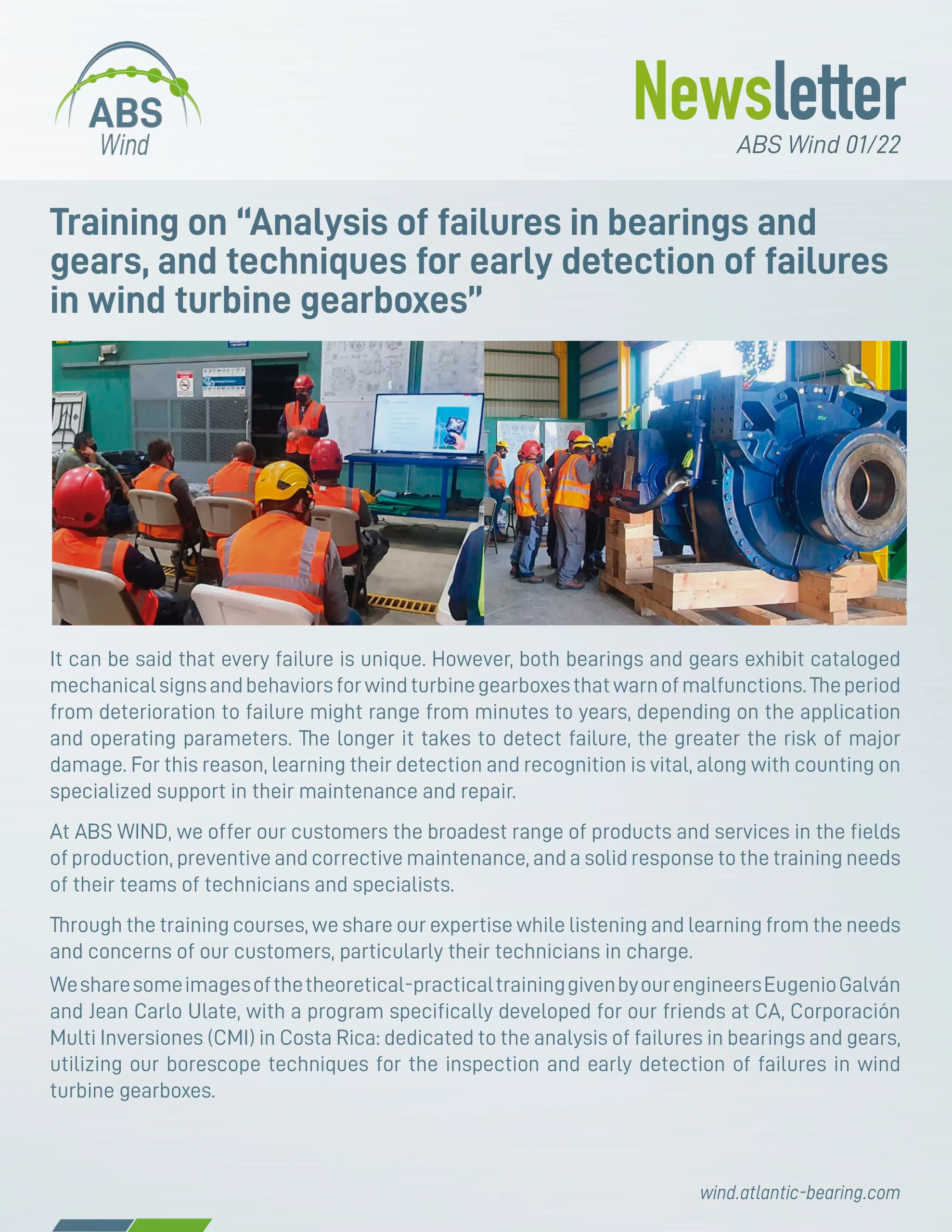

We share some images of the theoretical-practical training given by our engineers Eugenio Galván and Jean Carlo Ulate, with a program specifically developed for our friends at CA, Corporación Multi Inversiones (CMI) in Costa Rica: dedicated to the analysis of failures in bearings and gears, utilizing our borescope techniques for the inspection and early detection of failures in wind turbine gearboxes.