The ABS engineering department conducted a detailed study of the old drive system and proposed upgrading it with an ACS brand cardan shaft, with better production performance, longer life and lower maintenance costs.

Design and manufacture of cardan shaft for hot rolling mill 1 structural steel profiles at the TERNIUM Manizales plant

View in Newsletter pdf format

Ternium Colombia is the main producer of long steel in the country, with the capacity to supply a wide range of products to its main industries. The company has five production facilities in Colombia located in Manizales, Cali, Itagü, Barranquilla, and Palmar de Varela, Atlantico.

Operation Background

ABS engineering services supports all production systems involved in the whole steelmaking process: from iron ore extraction to the manufacture of high-quality products for the most demanding sectors.

ABS has a long history of collaborating with Ternium in different projects related to engineering solutions for the repair, maintenance, and supply for the power transmission components of its production systems. This relationship spans both its plants in Colombia and for some of its production centers in other countries.

The project described here has to do with the engineering study, design, and manufacturing of a cardan shaft to improve the transmission for one of the hot rolling mills in the Manizales, Colombia located Ternium plant.

The case

Ternium’s plant in Manizales has a hot rolling mill, which is composed of a roughing mill and a continuous mill driven by means of pad-connected extension-type coupling systems; an old mechanical system that was widely used years ago. These older systems often causes failures, increases the risk and cost of maintenance, and slows down production rate.

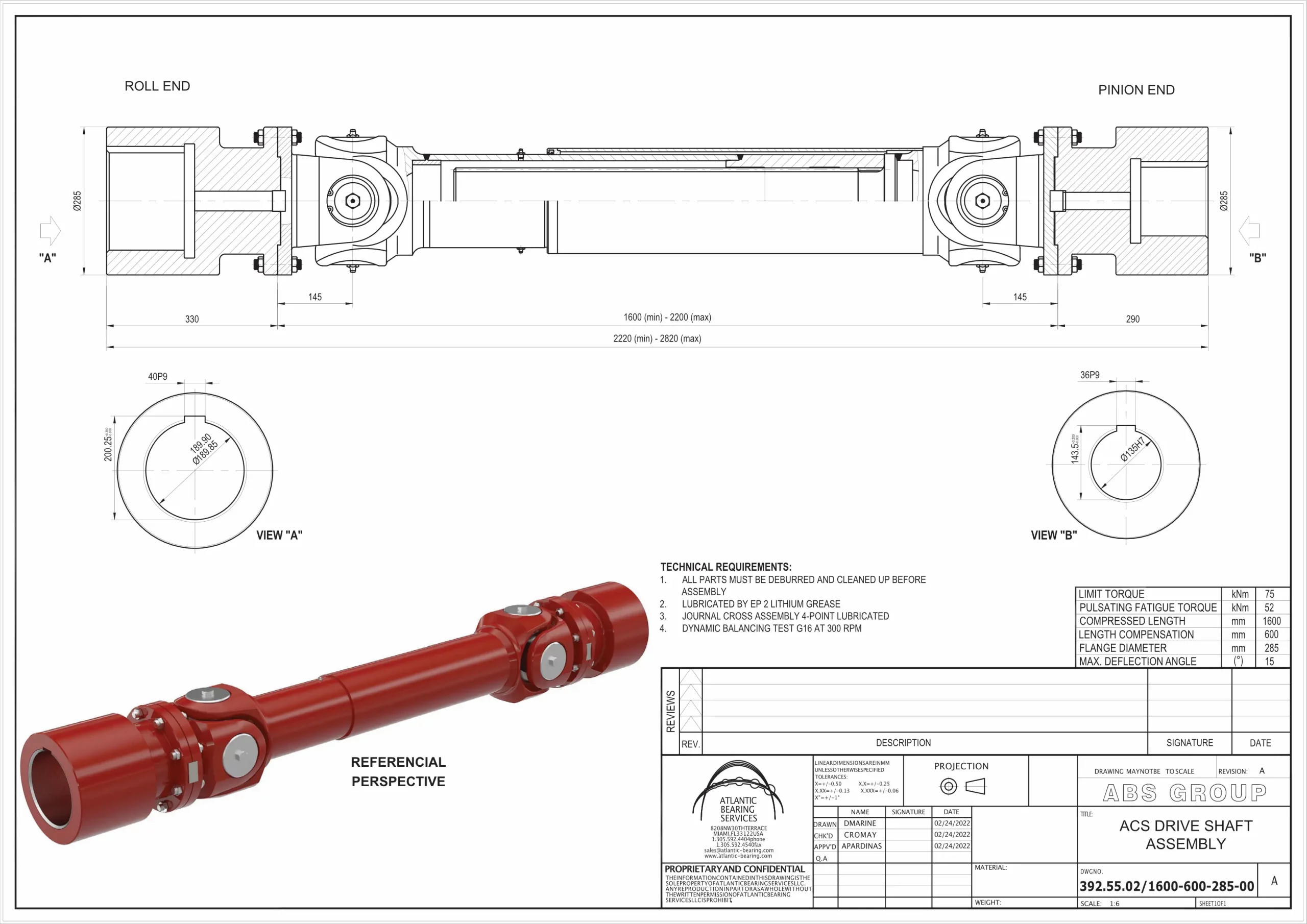

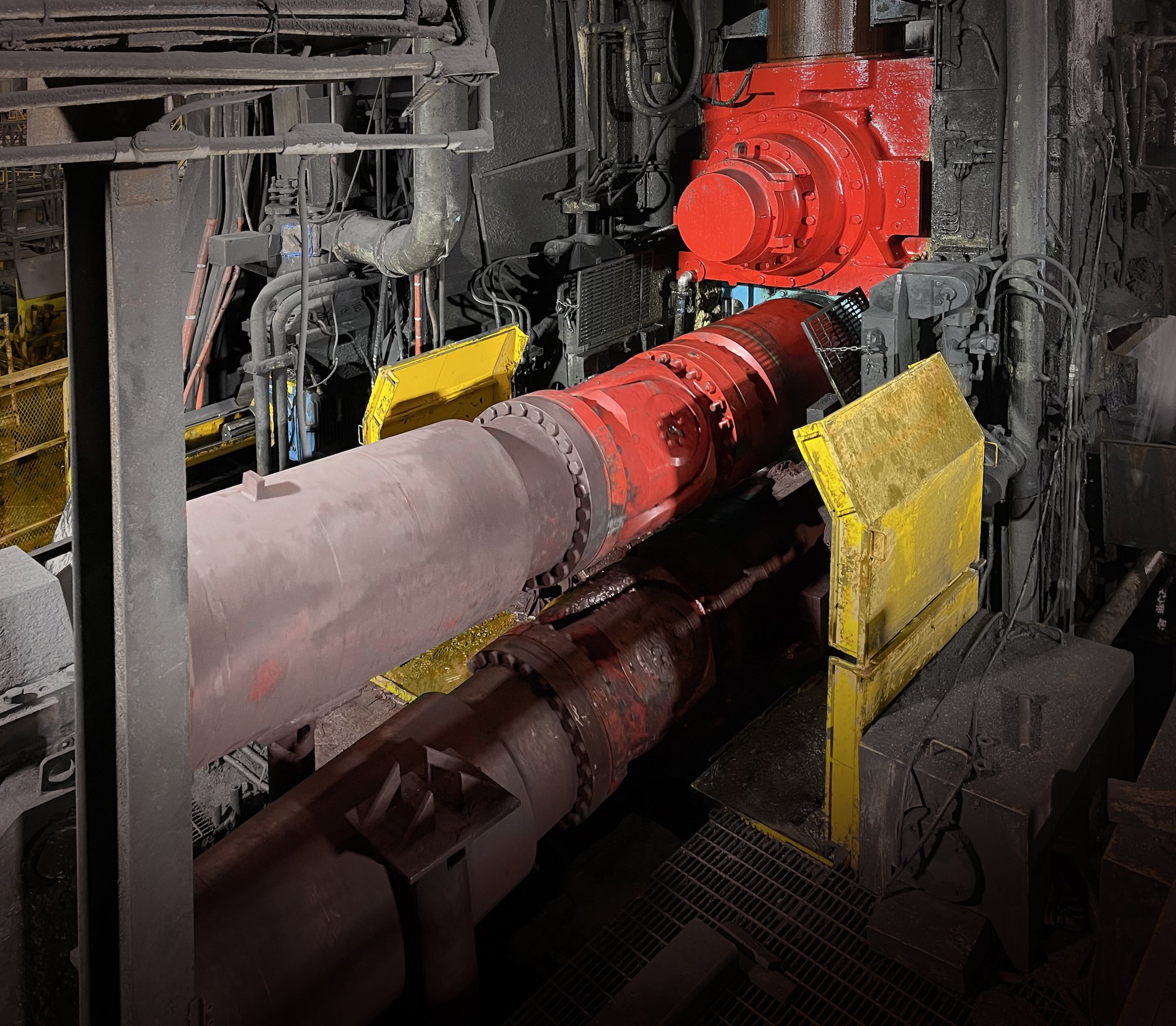

Old system and new ACS cardan shaft designed by ABS:

Technical Solution

The ABS engineering department conducted a detailed study of the old drive system and proposed upgrading it with an ACS brand cardan shaft with better production performance, longer life, and lower maintenance costs.

Within the engineering study, a general solution was also assessed for the use of the same type / reference of cardan shaft in four different rolling drive systems considering that each system has different sizes, powers, torques, etc; a solution that would optimize production and overall maintenance cost. At the same time, the lifetime of each cardan shaft working in the different rolling drive systems was determined, so that our customer, Ternium, could have a clear view of cost savings and production optimization.

To facilitate the transition to this solution, ABS began by manufacturing the cardan shaft for the rolling drive system operating under the most critical conditions, a methodology that ensures optimum performance of the cardan shaft in the rest of the drive systems assessed.

Currently, as mentioned above, the complete engineering study for this solution has been successfully presented, and the execution phases are being evaluated and planned.

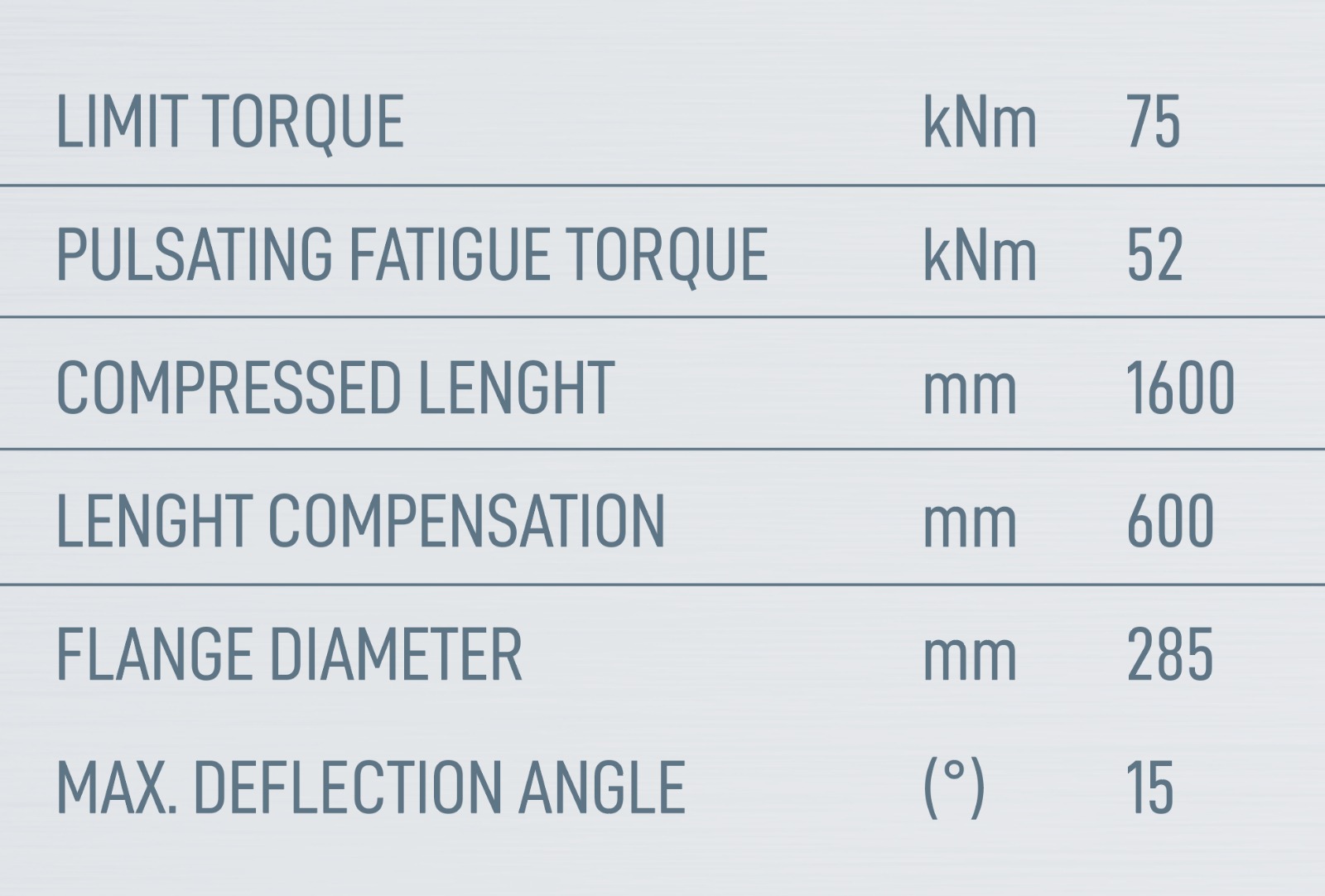

Technical details of the ACS cardan shaft

ACS – Atlantic Cardan Shafts, an ABS brand

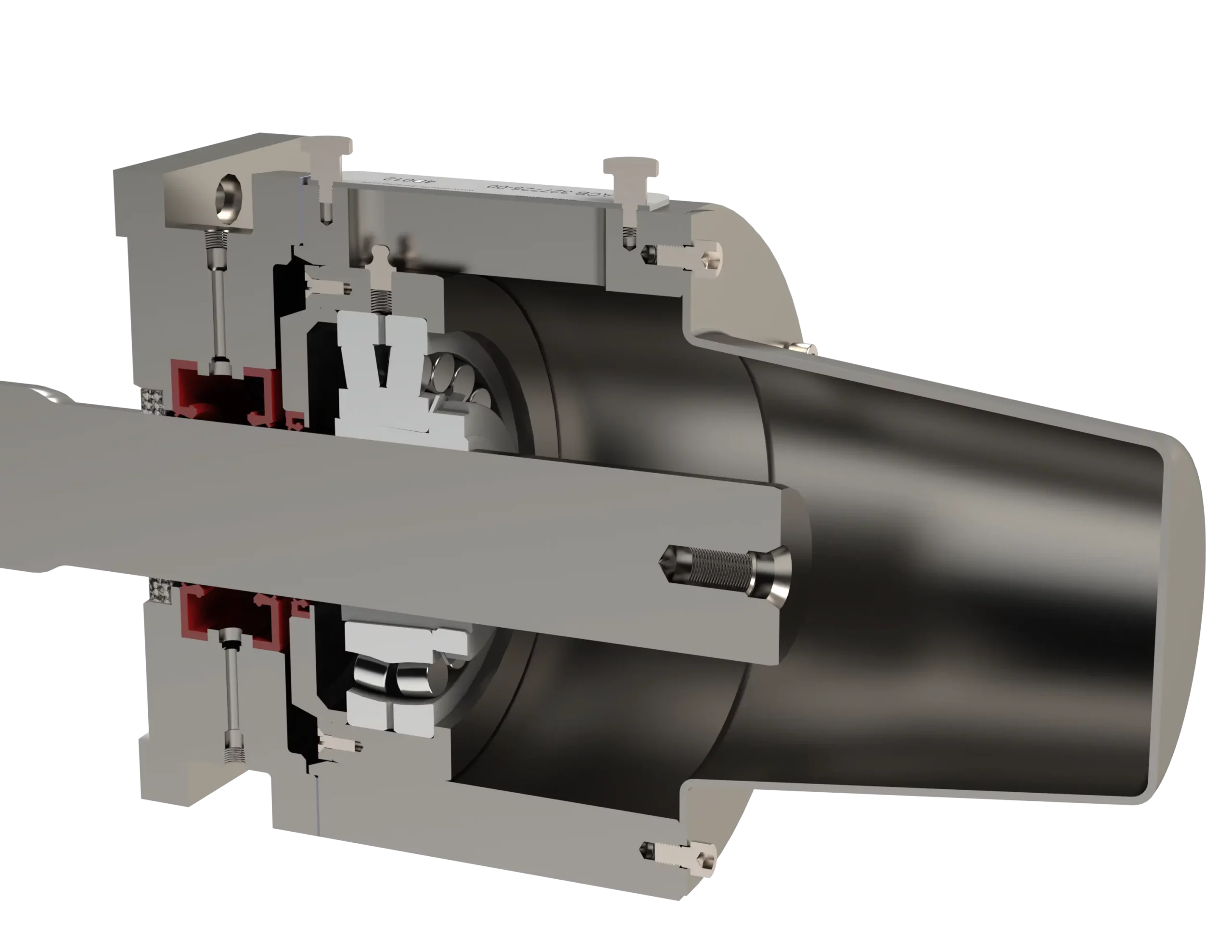

ACS was established as a supplier of highly engineered, custom-designed cardan shafts with the objective of guaranteeing superior performance and extending the service life of production equipment for heavy industry. Each one of the components that make up our cardan shafts are manufactured with the highest quality steels and steel alloys and comply with the most demanding quality standards in the market.