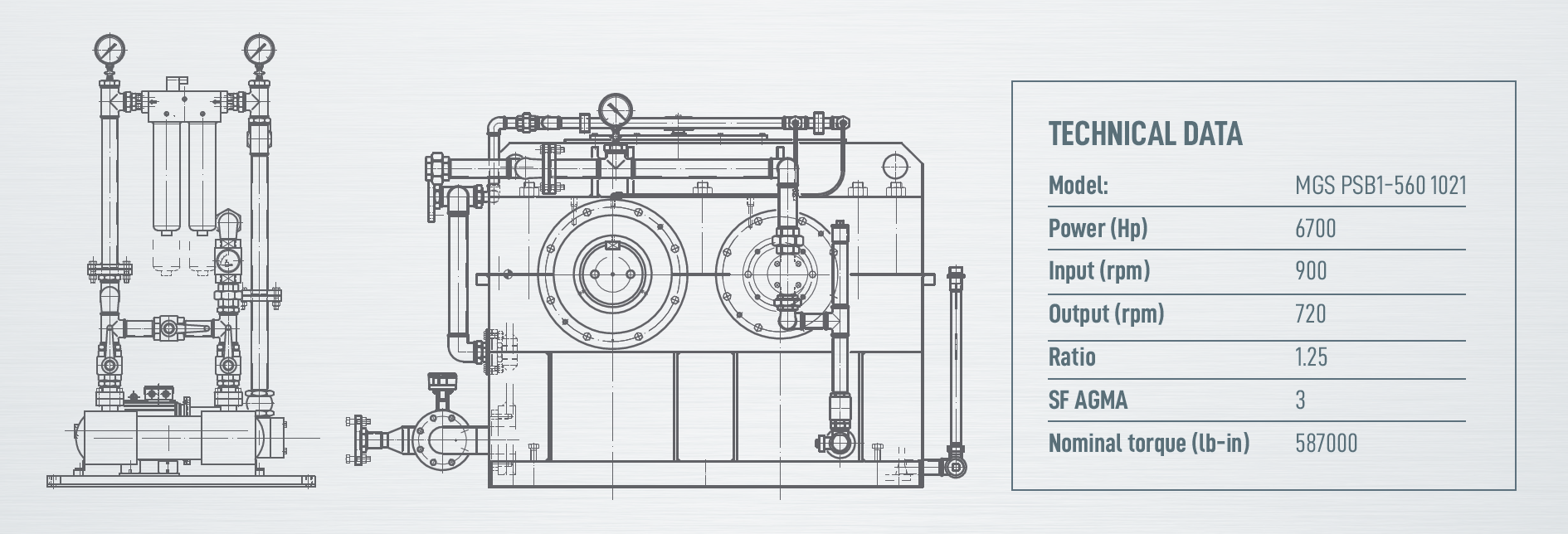

The Santa Ana Sugar mill installed an MGS PSB1-560 1021 gearbox on October 2017, designed to transmit 5,000 kW with an AGMA service factor of 3 and a transmission ratio of 1.25

Special manufacturing of 6700 hp shredder gearbox – Ingenio Santa Ana

Description

ABS brand, MGS Gears, has played a significant role in driving advancements in power transmission equipment within the Latin American SUGAR market. The company has been actively involved in the design and manufacturing of numerous specialized gearboxes specifically tailored for sugarcane preparation in various sugar mills. This valuable participation has allowed MGS to contribute to the enhancement of operational efficiency and productivity in the industry.

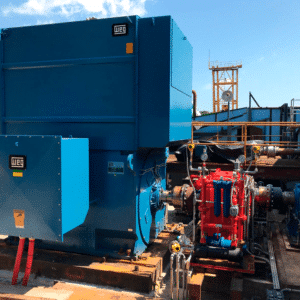

In 2017, at Ingenio Santa Ana / Santa Ana Sugar Mill, which was commencing its 48th sugarcane harvest since 1969, a notable success story unfolded. ABS Atlantic Bearing had the opportunity to collaborate closely with engineers from the sugar mill itself, undertaking the development, installation, and extended trial operation of the MGS PSB1-560 1021 gearbox.

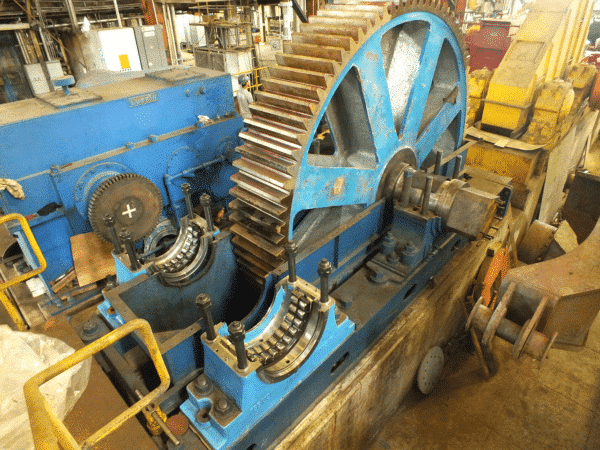

This gearbox was meticulously designed to transmit a power of 6700 Hp featuring an AGMA service factor of 3 and a gear ratio of 1.25. The manufacturing took place at the state-of-the-art facilities of MGS Gears, situated in Rho, Italy.

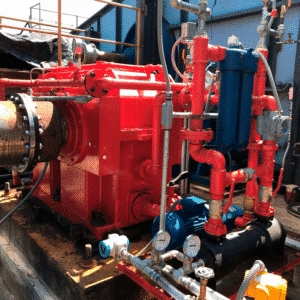

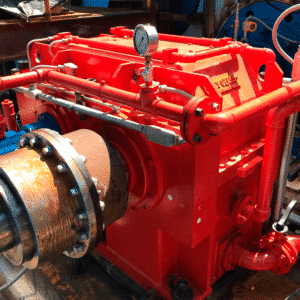

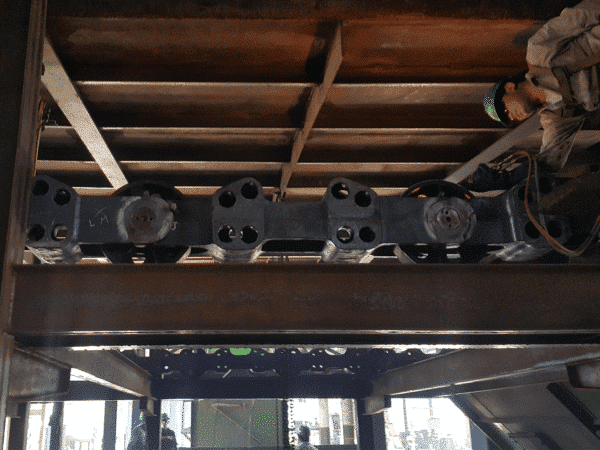

The gearbox plays a crucial role in the drive system of a Maxcell hammer shredder, produced by Dedini, which boasts an impressive configuration of 176 hammers and the capacity to shred up to 20,000 tons of sugarcane per day. It seamlessly receives motion from a three-phase induction motor, equipped with slip rings, delivering a power rating of 6700 Hp and operating at a synchronous rotation frequency of 900 rpm. The gearbox itself is a parallel reducer featuring a bi-helical gear stage, constructed using cutting-edge technology. It incorporates hardened steel and precision-ground teeth, meticulously manufactured to meet tolerances 3 and 4 in accordance with ISO standards.

The gear synthesis of this gearbox, with carefully selected backlash and module, allows for proper tuning with the driven machine, ensuring optimal operation in the extreme application for which it was designed. Additionally, the gearbox is equipped with a factory-mounted electronic system for measuring the temperature of each bearing, capable of issuing alarm signals and triggering shutdown. The lubrication system includes a flow meter, and the main mechanical pump has an electric backup pump. In addition, there is a signal indicating the cleanliness status of the filters and an internal oil level (added by the customer). This complete system is ready to be connected to the customer’s Automation system through a standard 4-20 mA signal.

The client – Compañía Agrícola Santa Ana

“The MGS Gearbox of the shredder at TA has worked perfectly during the 7 harvest seasons it has been in operation.The tooth settlement after this time is excellent. But the best part has been the technical support from ABS; it has truly been of a very high level. Therefore, I believe that we have not only purchased equipment but also gained a trusted provider.”

-Orlando Pinzón, Industrial Operations Manager

ABS & MGS supply for the Sugar Industry in Guatemala

ABS & MGSs had the opportunity to collaborate in the updating, repowering, speed changes, and provision of new equipment for the preparation of cane roots in more than 20 mills in the region over the last ten years. More than 30 projects have been completed, including generation equipment in motors, couplings, high reliability reducers, and specialized bearings for high fluctuating loads applications.