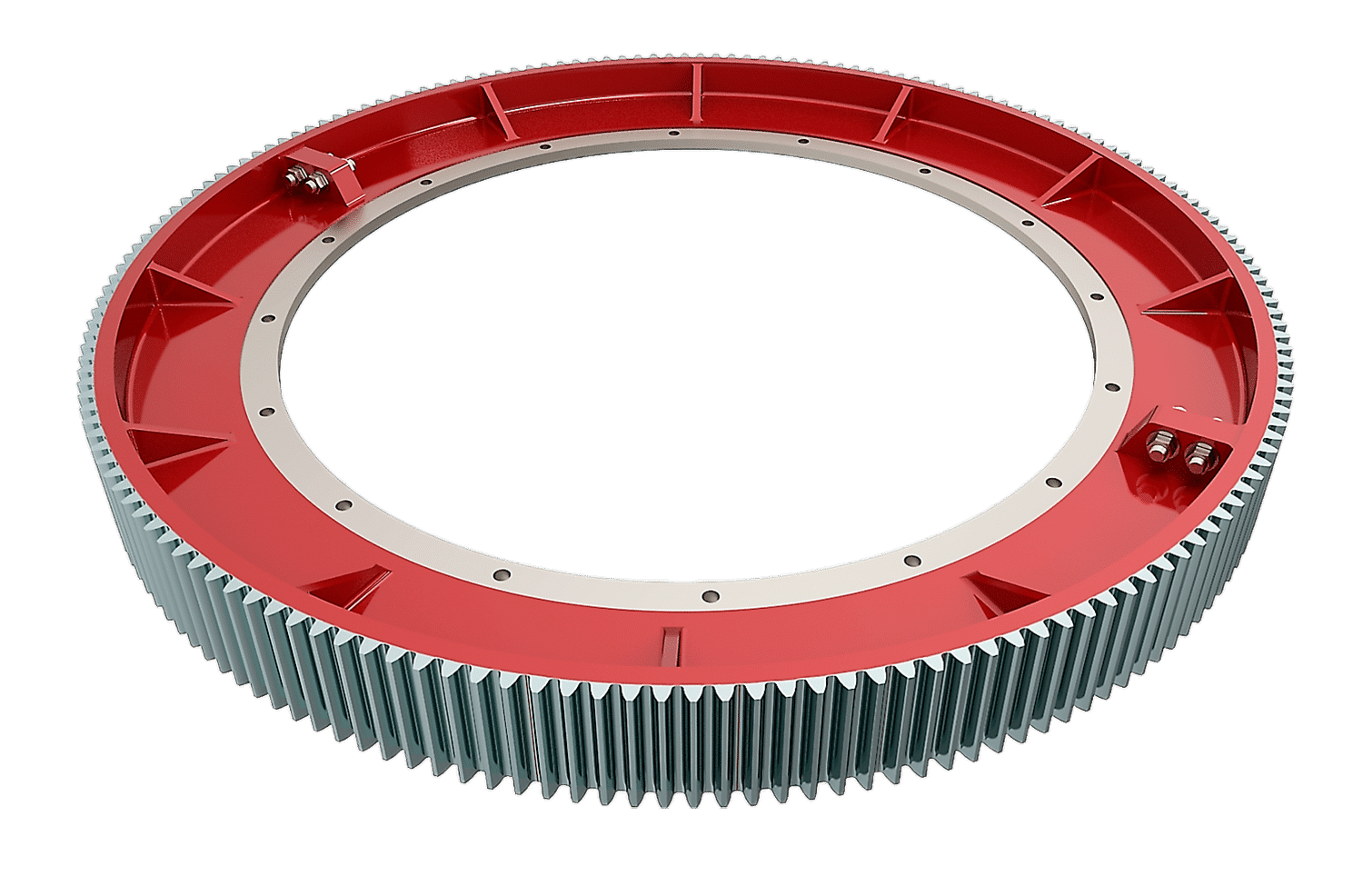

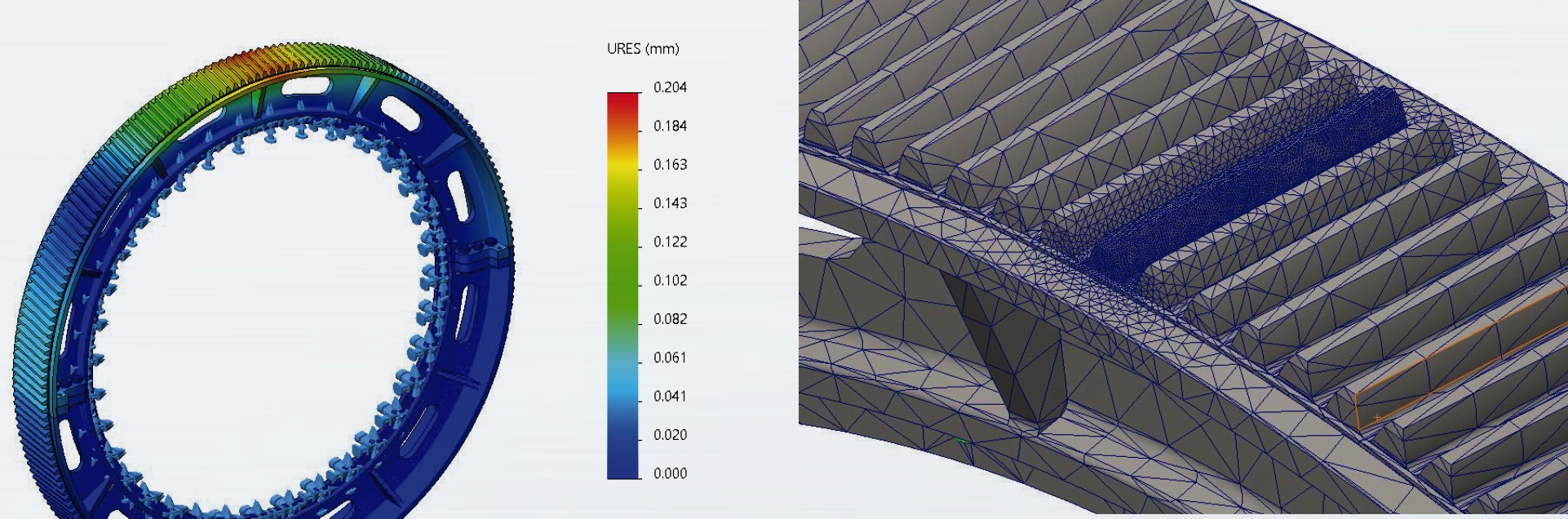

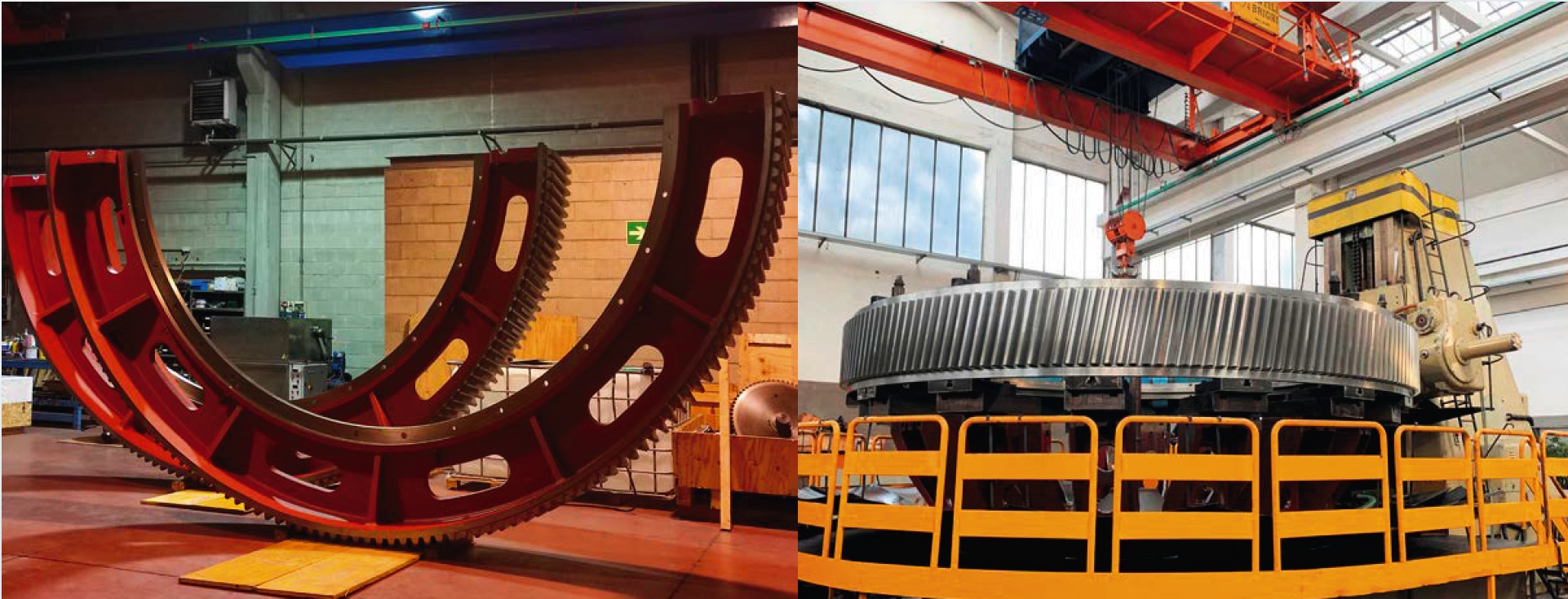

Girth Gears from ABS are engineered for heavy-duty industrial applications, delivering reliable power transmission for large rotating systems such as ball mills, kilns, and dryers. Made from high-quality, wear-resistant materials, ABS Girth Gears are designed to withstand the stresses of continuous operation, ensuring long service life and minimal maintenance. These gears offer precise alignment and load distribution, providing smooth and efficient torque transmission even under extreme operating conditions.

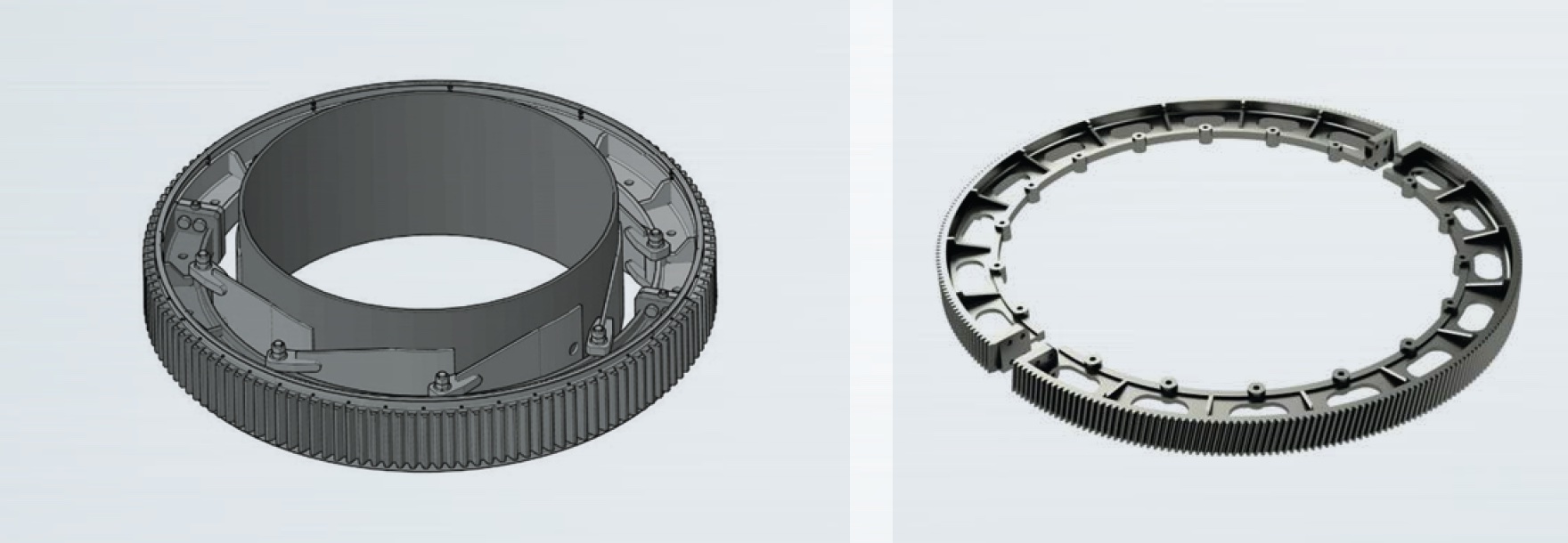

Custom-designed to meet specific operational requirements, ABS Girth Gears can be manufactured in a wide range of sizes and configurations. With advanced manufacturing techniques, including optimized gear tooth profiles and surface finishes, our gears minimize friction, reduce wear, and ensure high efficiency, making them ideal for industries such as mining, cement, steel, and sugar.

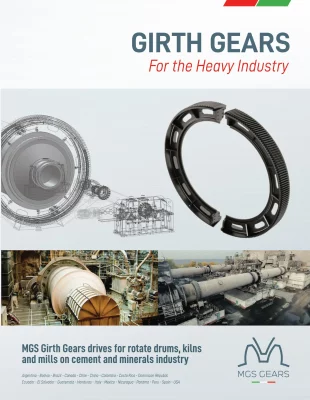

Girth gears are utilized in a variety of mining, cement, and minerals processing applications where downtime is not an option, such as copper, gold, silver, platinum, and iron ore production.