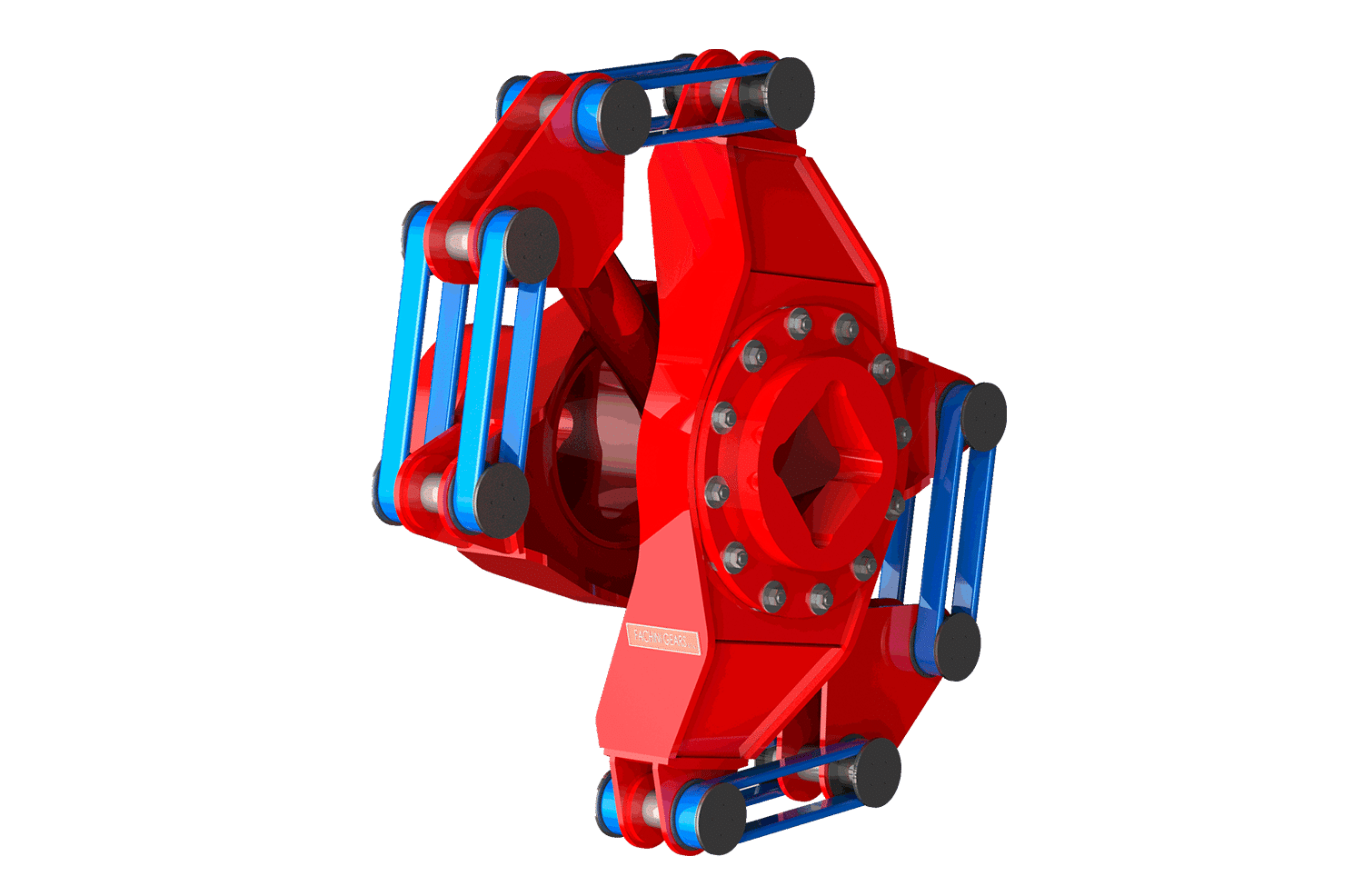

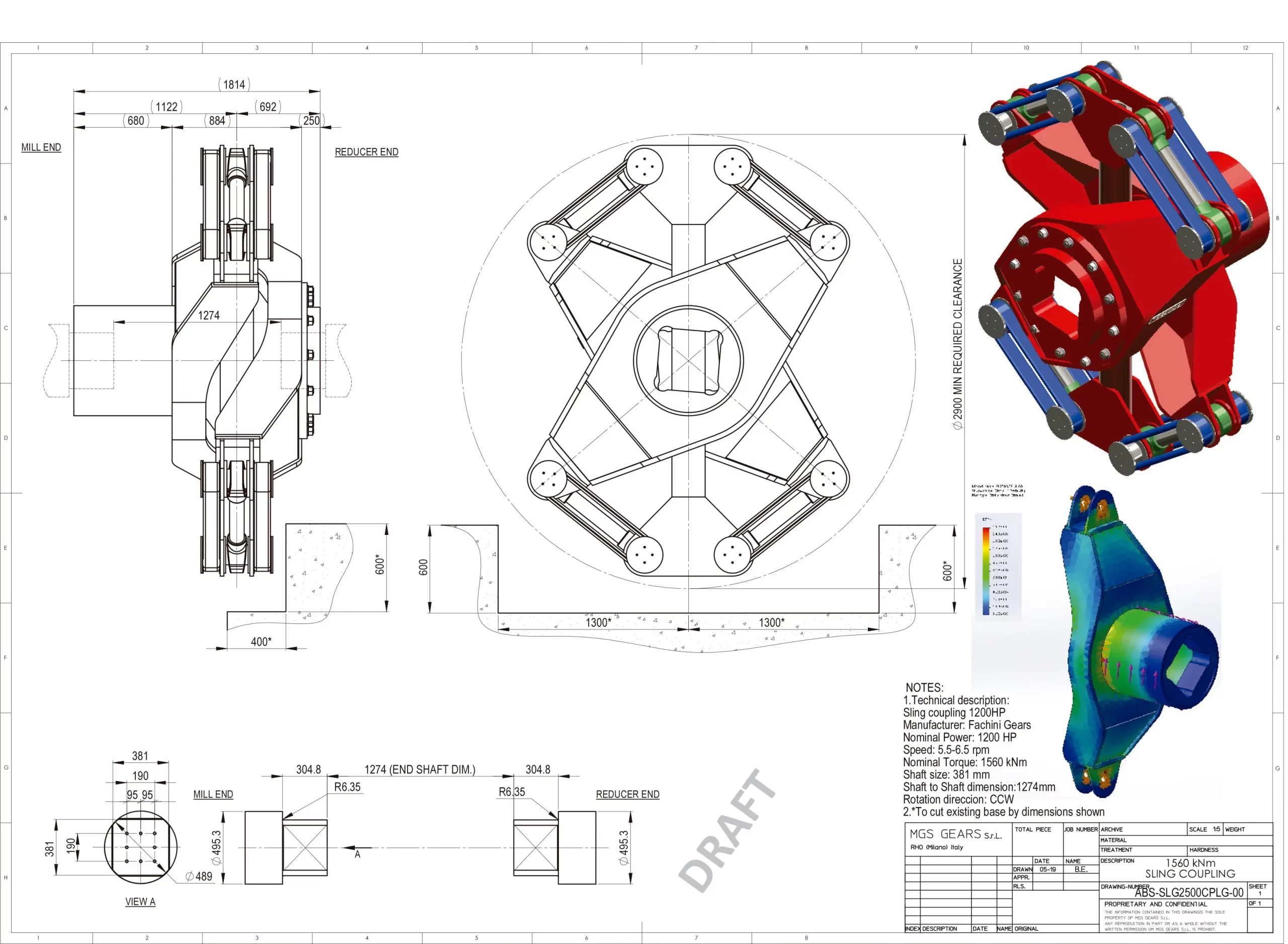

The Sling Coupling is a revolutionary concept for transmitting torque from the gear to the mill top in heavy-duty industrial applications. Designed to replace traditional square couplings and tail bars, the Sling Coupling consists of a driving and driven half, connected by flexible polyester slings. This innovative design allows the coupling to accommodate significant misalignment between the gear and the mill top roller, ensuring smooth power transmission and reducing mechanical stress.

The Sling Coupling directly connects the final speed reducer of the mill drive to the top roller, with the driving half secured to the square end of the speed reducer output shaft and the driven half attached to the square end of the mill’s top roller. The use of polyester slings provides flexibility, absorbing axial and radial misalignments without generating the high bending moments associated with traditional couplings. This results in enhanced mill performance, lower power consumption, and minimal maintenance.