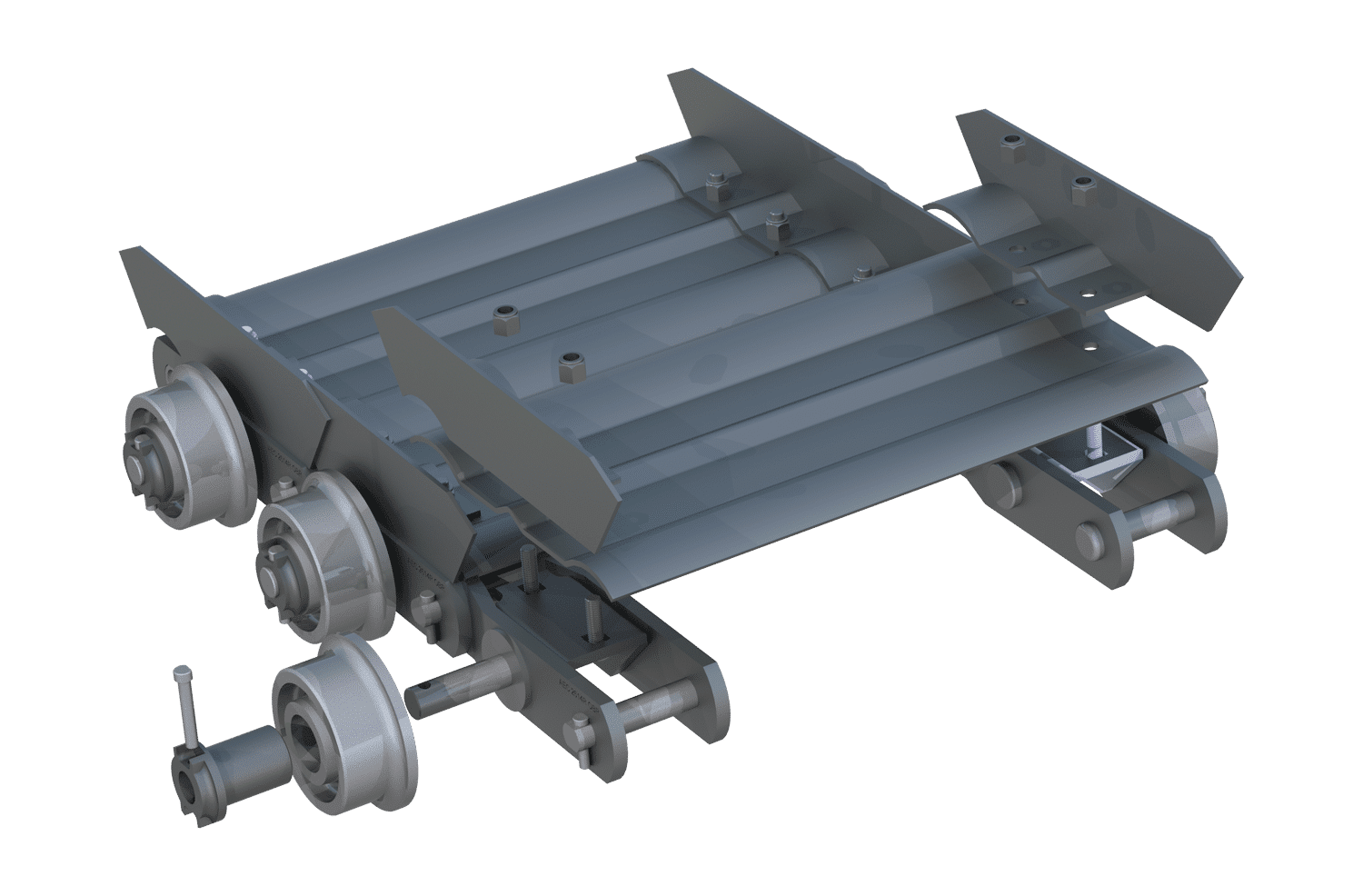

Our AEC brand Apron Conveyors are powered by a cycle-running chain, designed to transport a wide range of bulk materials in both horizontal and inclined directions. With carrying and running components made entirely of metal, these conveyors excel in handling materials with higher bulk density, sharp edges, and high abrasion resistance. Additionally, apron conveyors are ideal for transporting materials at elevated temperatures, making them perfect for industries requiring robust and reliable solutions. Commonly used in mining, metallurgy, coal, and chemical industries, apron conveyors efficiently move sharp, burning, and corrosive materials, ensuring smooth operation in the most demanding environments.

Home » product » Engineering Chains »