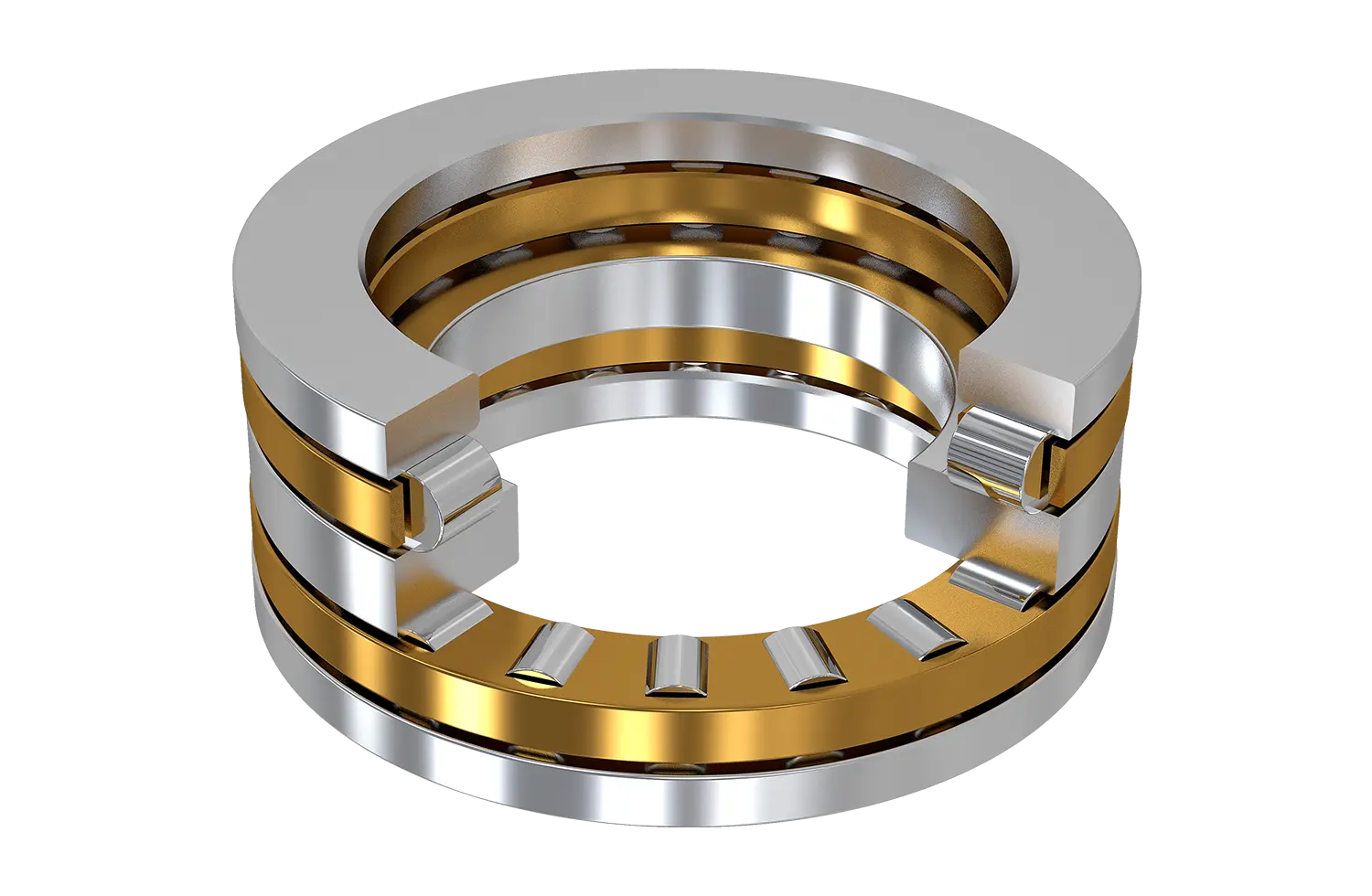

Cylindrical Roller Thrust Bearings from ABS are engineered to handle large axial thrust loads, providing robust support in heavy-duty applications. Commonly used in gear assemblies, these bearings are crucial for supporting thrust loads generated by helical gears with angled teeth, ensuring smooth and reliable operation. Designed with a washer-shaped raceway ring—comprising a shaft washer and a seat washer—along with cylindrical rollers and a cage assembly, these bearings ensure optimal load distribution across the rollers and raceway surfaces.

The cylindrical rollers feature engineered convex surfaces, allowing for even pressure distribution, which enhances performance and durability. These bearings are ideal for low-speed applications that require high axial load capacity without constraining radial movement. With their large axial load capacity and strong axial rigidity, ABS Roller Thrust Bearings provide exceptional stability and reliability in demanding industrial environments.