Precision that Moves the World:

MGS Gears in the Panama Canal

More than 12,000 vessels transit the Panama Canal each year, taking advantage of its vital link between the Atlantic and Pacific oceans. To pass through the locks, ships are guided and braked by electric rack and pinion locomotives running along the lock walls. These locomotives are a critical safety feature, preventing uncontrolled movement that could damage gates and cause catastrophic flooding downstream. With nearly 100 locomotives in service, their mechanisms are subject to the highest standards of reliability and quality control.

Each gear must overcome a triple challenge: withstand extreme humidity and salinity, maintain precise alignment under load, and endure continuous mechanical stress without failure. Even a single malfunction could disrupt global cargo movement and trigger multimillion-dollar operational delays

High-Precision Carburized

MGS Gears for the Panama Canal

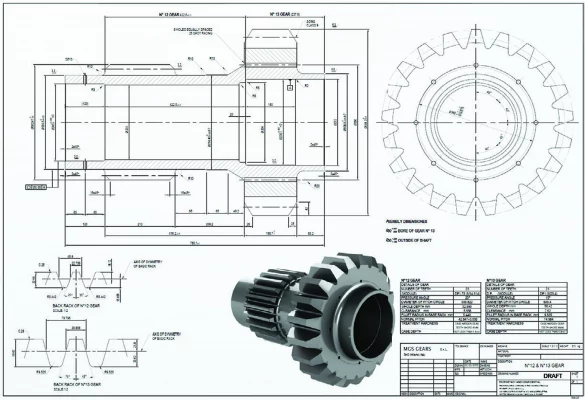

As shown in the accompanying illustration, the pinion shaft assemblies (No. 12 and No. 13) are mounted on separate pairs of M2000 locomotive wheels. Each is crafted from premium AISI 4320 alloy steel, precision cut using state-of-the-art gear hobbers. After machining, the gears undergo controlled carburizing and hardening to 60 to 62 HRC, with final tooth profiles ground to exacting tolerances on last-generation gear grinders. Each gear was subjected to ultrasonic inspection, dimensional verification, and non-destructive testing at multiple stages of production. The entire project was executed under an ISO 9001-certified quality management system, ensuring complete traceability and rigorous compliance with the technical specifications established by the Panama Canal Authority.

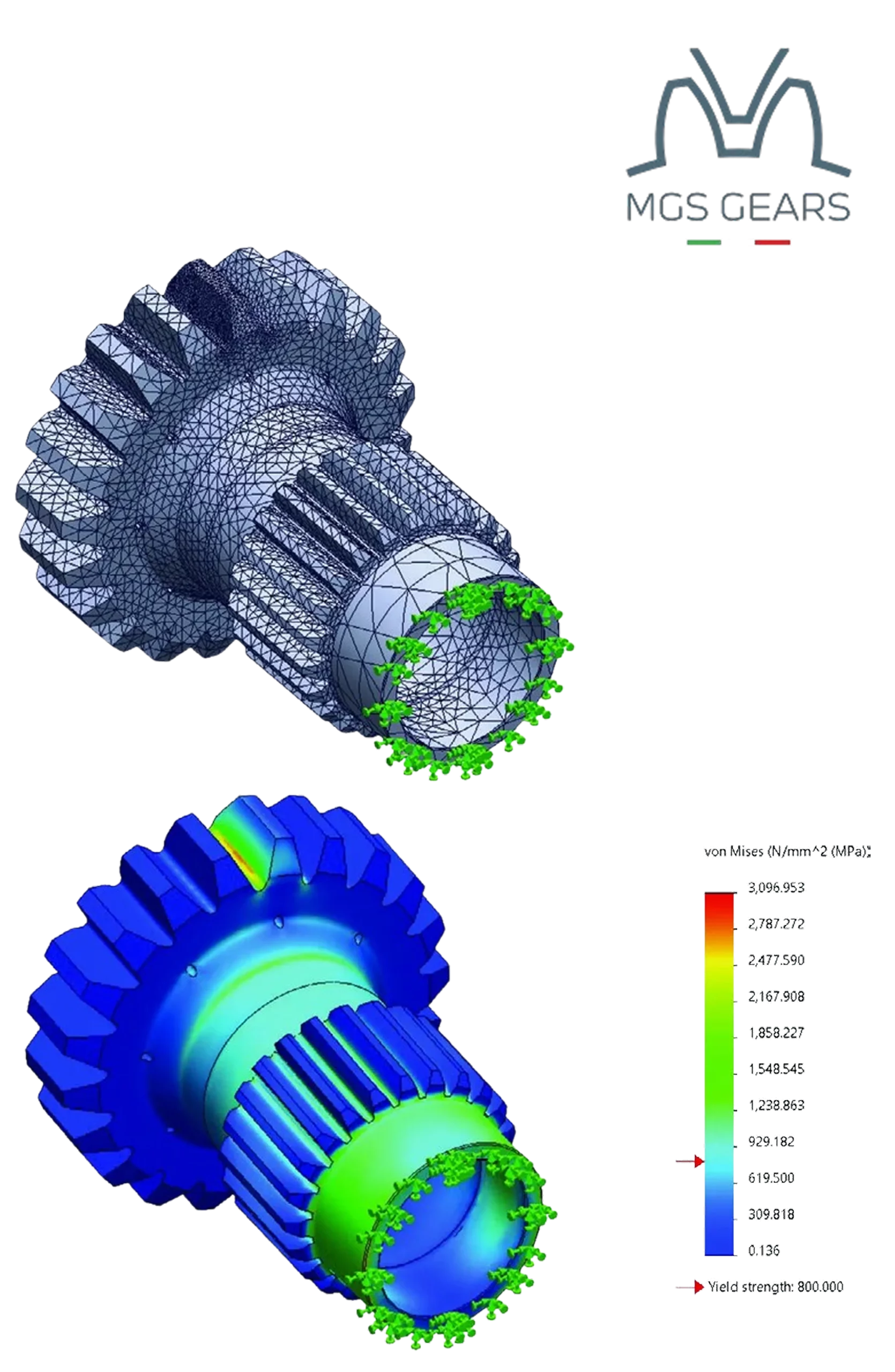

MGS Gears FEM simulation

Within a tight timeframe and under complex logistical conditions, ABS, through its specialized brand MGS Gears, successfully manufactured and delivered 16 units on schedule, fully aligned with the Panama Canal’s critical maintenance windows. This achievement required meticulous technical planning, close coordination with operations, and flawless execution.

From design to delivery, the project involved rigorous cross validation procedures, multi-site quality control, and agile coordination across engineering, manufacturing, and QA teams. The responsiveness and reliability of ABS and its MGS Gears division played a key role in reinforcing the Panama Canal Authority’s trust in this highly specialized solution

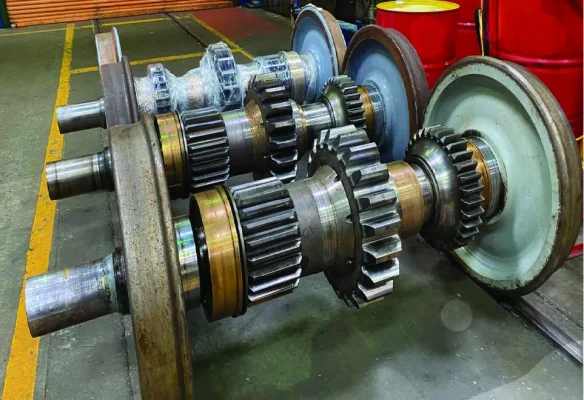

Assemblies of wheels 12 & 13 mounted in locomotive wheelsets.

MGS Gears finished and in a packing process

For ABS, it was both an honor and a commitment to receive the original order in 2020 for the manufacture of pinion shafts No. 12 and No. 13, key components in the gear train of the Mitsubishi M2000 locomotives, as commissioned by the Panama Canal Authority (PCA). Since that first contract, ABS has continued supplying these assemblies in multiple deliveries over the years. While ABS serves a distinguished customer base, the ACP holds a place at the very top, a position earned through the proven performance of MGS Gears, a division of the ABS Group dedicated to the high-level design and development of gear pairs and complete gear units

Engineering Excellence Under Pressure

- Achieving micron-level tolerances to ensure fl awless meshing with the rack rail system

- Preserving optimal surface hardness (60–62 HRC) without reducing core ductility and toughness

- Meeting critical maintenance window deadlines without sacrifi cing manufacturing integrity

- Operating under strict environmental controls to withstand high salinity, humidity, and tropical heat

Conclusion

Execution that Matches Engineering

At ABS, through MGS Gears, we deliver confidence. Our vision is clear: to be a global reference in critical components for infrastructures where downtime is not an option. Precision engineering is our language, and the Panama Canal is one of our proudest achievements