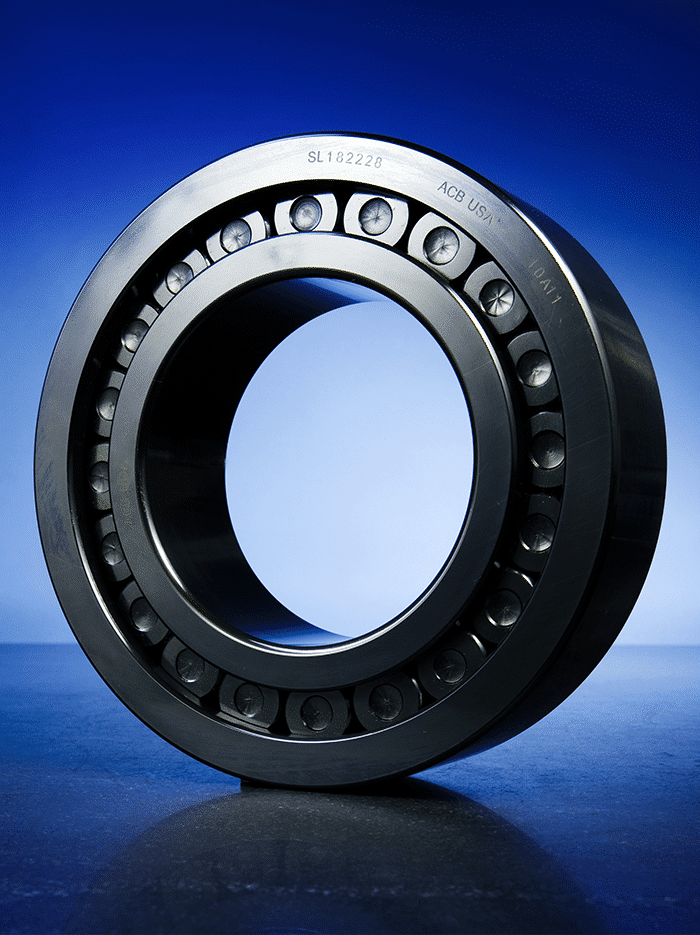

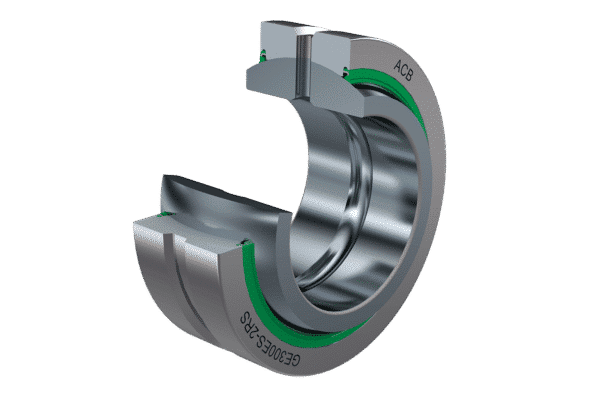

ACB bearings are subjected to a strict Quality Control (QC), where the specified manufacturing requirements are inspected, referencing the ISO 9001: 2000 standard. All key processes, from design to selection of materials, forging, heat treatment, grinding, and assembly operation, are carried out by our team of specialized engineers and supervised by our scientific department, and 100% of the parts are inspected during and after the manufacturing process in addition to performing and before shipment, a final inspection by sampling in our QC Laboratory.

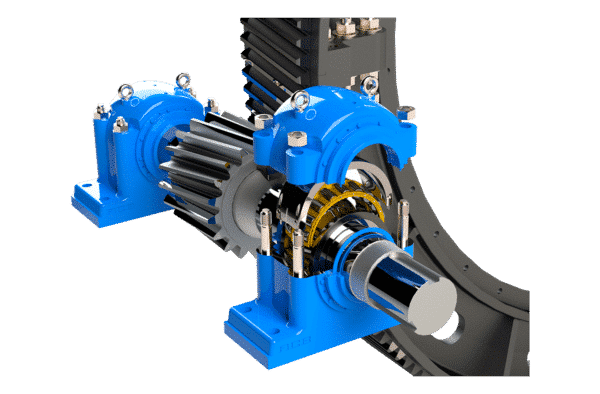

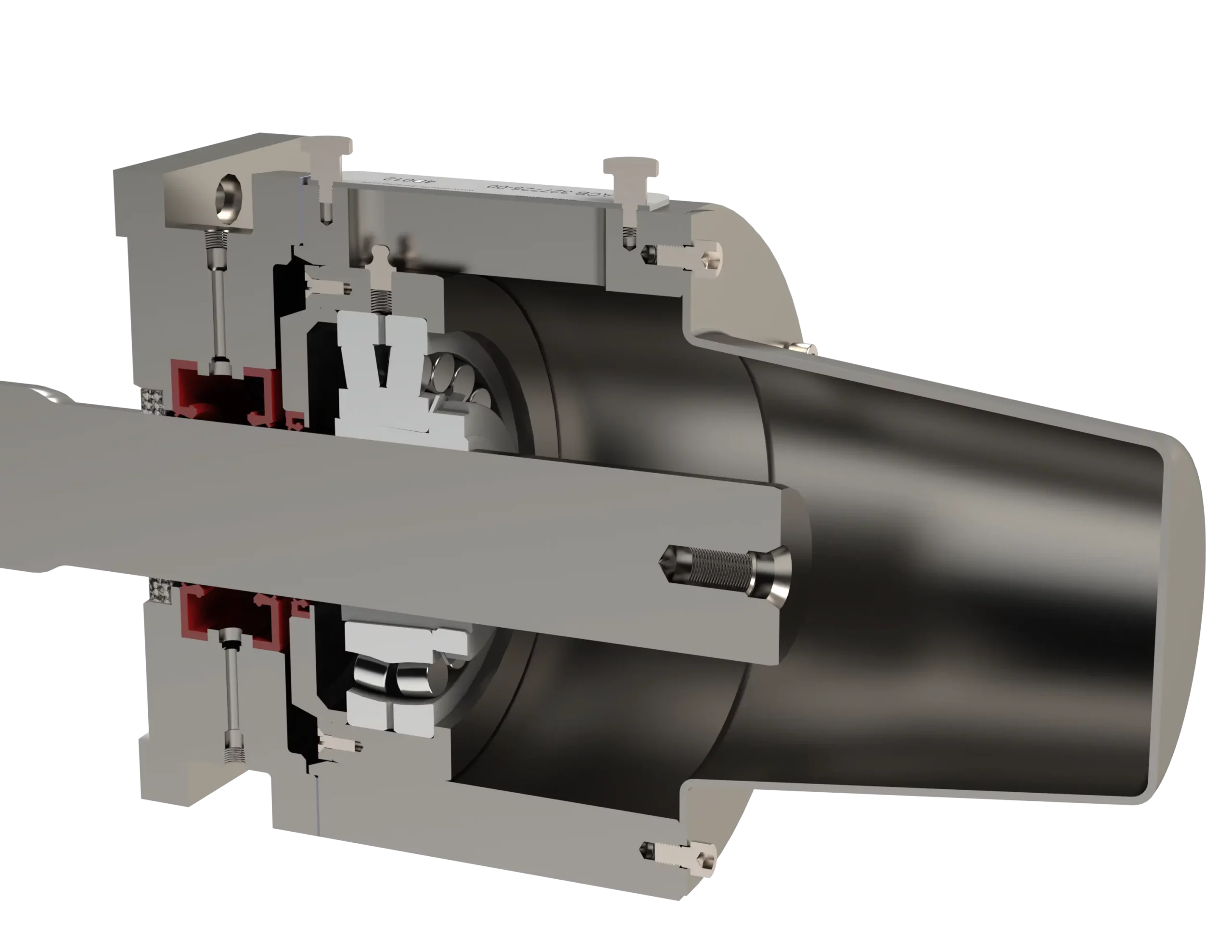

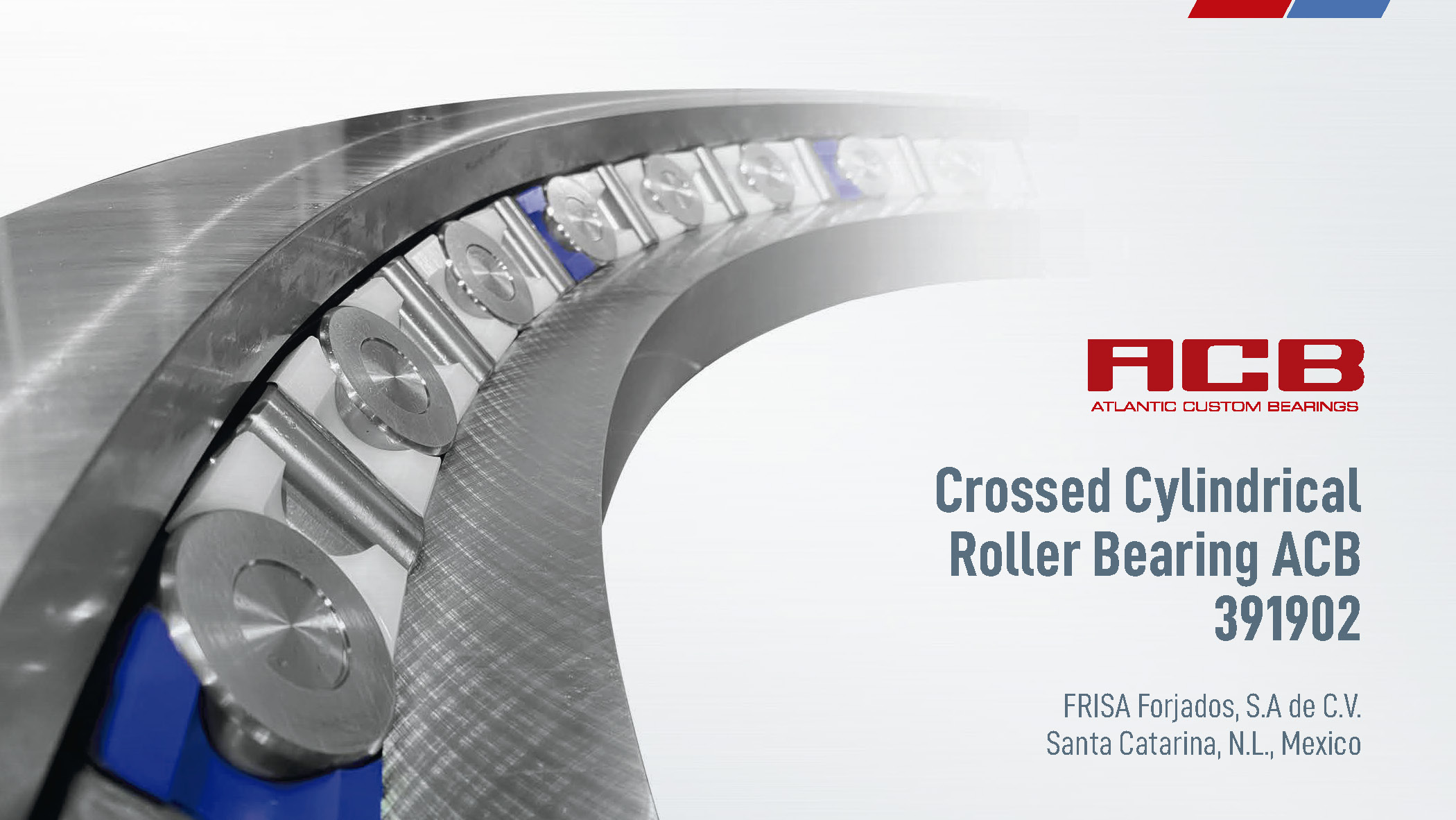

To minimize risks and achieve a response as adapted as possible, ACB also has the most advanced software for the design and evaluation of each bearing it manufactures. Through the well-known Finite Element Analysis (FEA), we realistically simulate the work of the bearing, subjecting it to the specific parameters and working conditions for which it will be required. Based on the results of the FEA, and if necessary, the component design can be modified to ensure its optimal performance in a real-world environment.

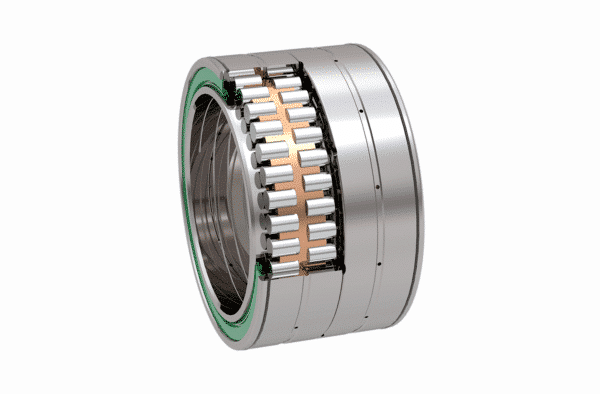

Moreover, if we have something clear, it is our inclination for projects that pose a challenge for our design and manufacturing department. We know that each mechanical component we design and manufacture represents a new step in offering our customers the most efficient and innovative custom-bearing solutions.