Second Life for Steel Bearings:

Extending Value, Minimizing Waste

Bearing Reconditioning Program for the Steel Industry

In today’s industrial landscape — where uptime, cost-efficiency, and sustainability are critical—bearing reconditioning

emerges as a high-impact strategy. ABS’s reconditioning program reflects a growing global trend: recovering high-value

components to like-new condition, reducing waste and cost while maintaining performance and safety.

ABS supports circular economy principles by offering technically validated reconditioning services. This initiative

targets key challenges in the steel rolling sector, extending bearing life, lowering total cost of ownership, and reducing

environmental impact.

Development and execution of a comprehensive bearing reconditioning program to extend

the life of large, high-performance bearings under heavy load and thermal conditions

What is Bearing Reconditioning?

It is the process of returning a used bearing to like-new condition using industry-standard inspection, cleaning, and precision machining—ensuring compliance with OEM specifications.

- Cleaning and dimensional verification

- Non-destructive testing and fatigue analysis

- Grinding and polishing raceways

- Replacement of components if necessary

- Reassembly, lubrication, and final QC

When is it Applicable?

- Bearings > 300 mm diameter

- Non-catastrophic surface wear

- Preventive maintenance windows

- Long lead times or supply chain constraints

TECHNICAL & OPERATIONAL CHALLENGES

Technical Risks

- Assessment accuracy: Misdiagnosing fatigue, spalling, or plastic deformation can undermine reliability

- Dimensional precision: Post-repair BEP (Bench End Play) and tolerances must match OEM specs

- Material integrity: Surface rework must not alter core metallurgical properties

- Component compatibility: Internal parts must match the original bearing geometry and materials

Operational Barriers

- Traceability: Full documentation is essential from disassembly through QC

- Handling and logistics: Bearings must be safely removed and transported without secondary damage

- Downtime risk: Turnaround time must be faster than new bearing lead time to justify adoption

- End-user confidence: Convincing maintenance and procurement teams of long-term reliability is key

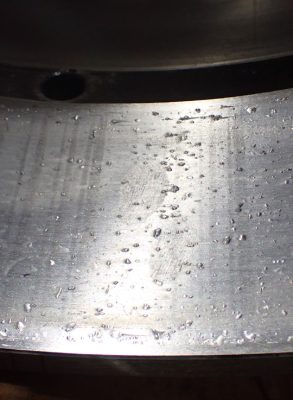

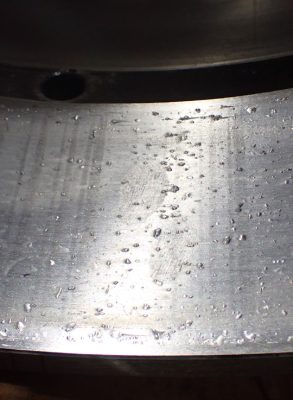

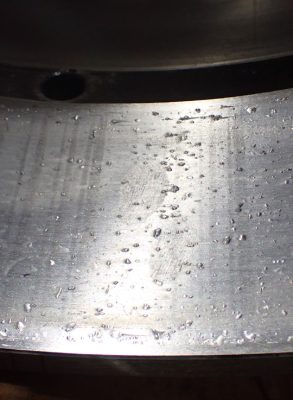

BEFORE RECONDITIONING

Receiving condition

Receiving condition

Receiving condition

Receiving condition

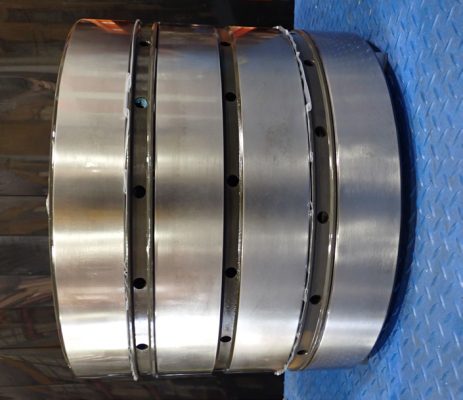

AFTER RECONDITIONING

Receiving condition

Receiving condition

Receiving condition

Engineering

Highlights

- Full restoration of bearing geometry through CNC regrinding

- BEP verification to ensure preload/load-sharing accuracy

- Non-destructive testing (NDT) for crack and hardness detection

- Polishing of raceways without undermining load-bearing capacity

- Reuse of bearing bodies with precision-fitted new internal components when required

Engineering Highlights

Cost Efficiency

- Reduces replacement costs by up to 60%

- Eliminates import delays and inventory issues

Operational Value

- Faster turnaround versus OEM procurement

- Extends uptime of critical line equipment

- Supports condition-based and predictive maintenance plans

Sustainability

- Minimizes scrap and energy use associated with new manufacturing

- Aligns with corporate sustainability and ESG goals

Global Benchmarks

Sustainability programs:

Promoting remanufacturing to improve

energy efficiency and resource use

Remanufacturing services:

Offering bearing reconditioning to reduce CO2

footprint and increase component longevity

Specialized programs

Reconditioning custom bearings with full traceability and performance validation

List of Key Applications for Bearing Reconditioning

- Rolling Mills (Hot and Cold)

- Continuous Casting Machines

- Converters & Steelmaking Equipment

- Ladle Turrets and Transfer Systems

- Coilers, Laying Heads, Pilger Mills

- Industrial Fans, Blowers, and Large Electric Motors

- Gearboxes and Drive Systems (Non-integrated Units)

CONCLUSIONS

ABS’s reconditioning program exemplifies how advanced maintenance practices can deliver both economic and environmental value. Our commitment to asset optimization, circular economy models, and operational excellence makes us a strategic partner for industrial leaders looking to modernize maintenance without compromising reliability.

For more information or to evaluate how bearing reconditioning could benefit your operation:

[email protected]

atlantic-bearing.com